THE 10th ALL IN PRINT CHINA

第十屆中國國際全印展

全印展

中國國際印刷技術及設備器材展

China International Exhibition for All Printing Technology & Equipment

October 12-16, 2026

上海新國際博覽中心

Shanghai New International Expo Centre

Supported by

<strike id="ay2s2"></strike>

THE 10th ALL IN PRINT CHINA

第十屆中國國際全印展

全印展

中國國際印刷技術及設備器材展

China International Exhibition for All Printing Technology & Equipment

October 12-16, 2026

上海新國際博覽中心

Shanghai New International Expo Centre

Supported by

Regions/Country:China

Dongguan Keqi Automation Equipment Co., Ltd. is the leading supplier for manufacturing, selling automatic packaging equipments, such as Automatic Tape application Machine, Plasma Surface Treatment System, Hot melt /cold Gluing Application,bar code and gluing detection system etc. Keqi solutions will fit for the packaging in the area of pharmaceutical, 3C, cosmetics, express delivery, and e-commerce packages , etc..

Detection system Quality assurance system

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Gluing gun Detection System,used for preventing of adhesive-missing, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process.

Product introduction:

Gun detection system ,This system works for gluing inspection and detection automatically.It’s widely used for preventing of adhesive-missing, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process. it can retect the error products automatically.

Cold Glue Spray Machine

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

KQ cold glue system has the characteristics of high efficiency, flexibility, good stability and easy maintenance.

Product introduction:

This model is set by 8'' or 15'' inches touch screen, each glue gun can be set 8 sections of glue sample. High precision components are equipped with high frequency solenoid valve to ensure not destroy the gluing operation when the machine is working at high speed. One-key switch for different types of product which in to control interface. Various types of glue guns, application of different situation and glue projects.

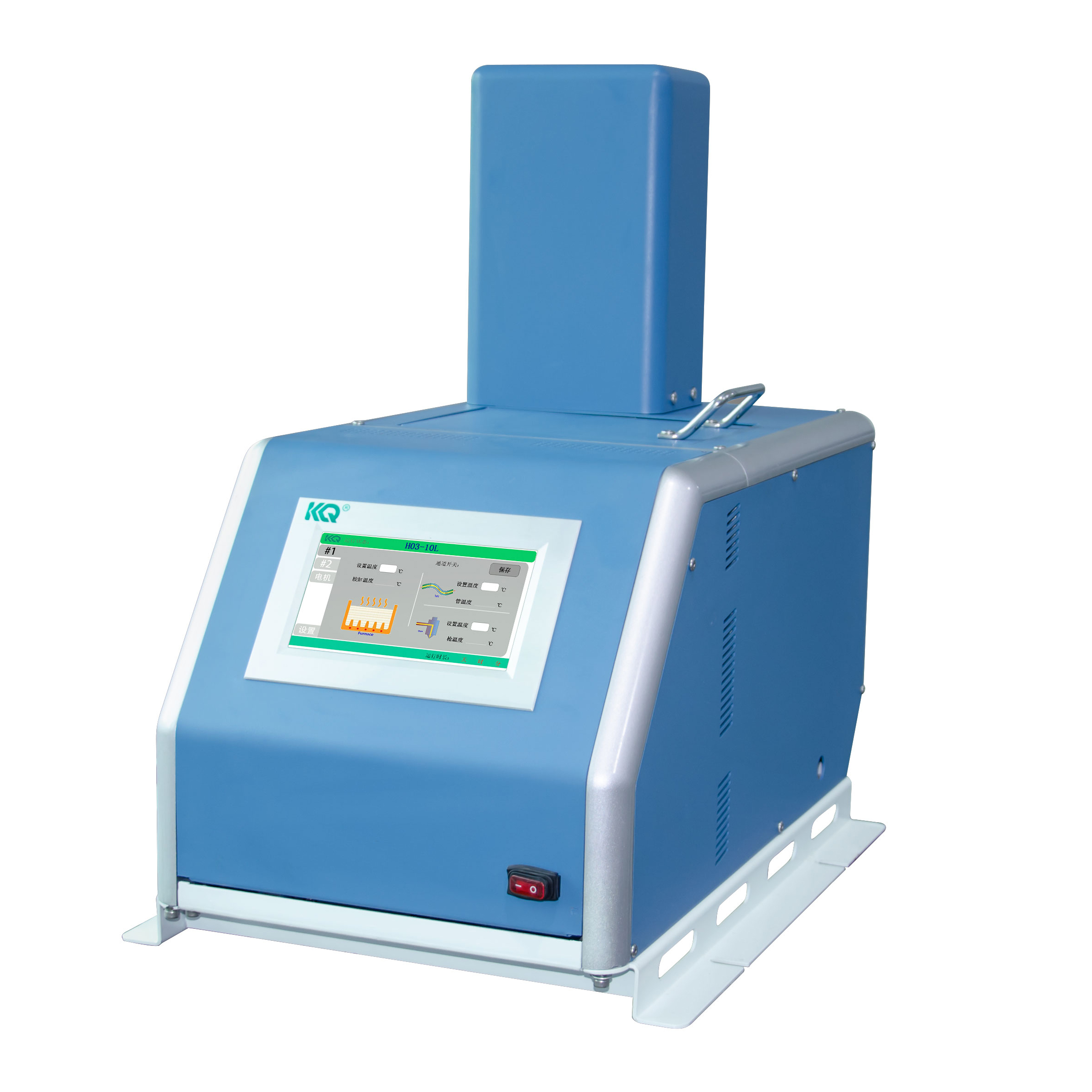

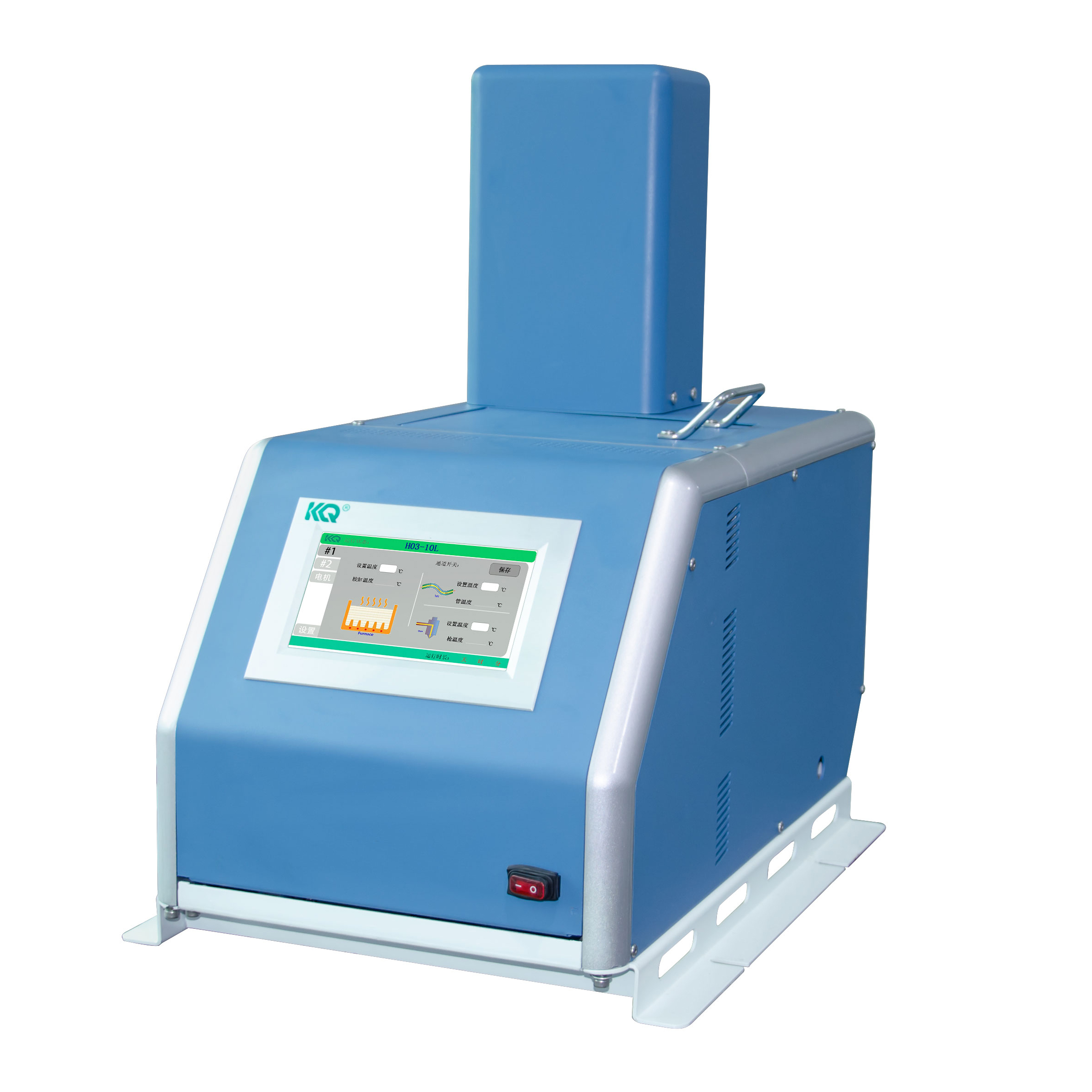

Hot Melt Dispensing Machine

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

The machine is suited for a precise dot and bead-line application at high speed.Can be flexibly used for different applications in diverse industries.

Product introduction:

This model is with Convenience Operation and Flexible Control. It can be set Auto-preheating time within a week, and can also be adjusted the temperature according to the glue characteristics. Glue gun / pump independently controls the modular of temperature.It is also with device insulation function and over-temperature protection. It displays the international temperature in Celsius and can be automatically shutdown due to the fault / malfunction.

Plasma Surface Treatment System

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Innovative technologies for surface activation and coating can effectively improve the product's surface dyne value and increase adhesion.

Product introduction:

It perfectly improves surface tension, prevents adhesive & bonding break, it's used on lamination / UV Coating by using cold glue or common adhesives, it reduces glue consumption and cost. It's equipped with folder gluer machine / ink-jet printer / assembly machine and making boxes machine in processing online. Its multiple protection switch & fault alarm are obtained the CE Certification standard. It's designed for folding cartons which are metalized with UV Coating or lamination. It applies plasma surface treatment system with standard cold glue instead of other expensive or special glue, and perfectly achieve perfect gluing quality and reducing production cost. It is optional for direct nozzle or rotary.

B Series Double Sides Tape Application Machine

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Adhesive incision for the tooth mouth,will not cause the damage to the product.

Product introduction:

This model is designed as a light machine, mainly pasting for carton boxes, envelopes, e-commerce bags with double-sided tape and easy tapes. It adopts high level raw materials and thickened wallboard design, famous brands of belt, motor and other key components, so that ensure the machine can be stably running for a long time under high speed. It's based on SCM technology, developed all of drive units with intelligent control and One-key Start Producing. It's equipped with slot coating guns & silicone tape applicator, scotch applicator, double-side tape applicator, tear tape applicator, folded device or customized parts. It is applicable for boxes, delivery bags, corrugated boxes, and smoke / wine boxes, gift boxes, art-ware adhesives, etc.

C Series Double Sides Tape Application Machine

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Adhesive incision for the tooth mouth,will not cause the damage to the product.

Product introduction:

This model is equipped with alignment unit, it highly improves the producing accuracy in processing, and also expands to install hot melt gun and release tape applicator, make sure meet customized demands. It is optional for the controller with 15 inches touch screen and easy operation. It adopts high level raw materials and thickened wallboard design, famous brands of belt, motor and other key components, so that ensure the machine can be stably running for a long time under high speed. Independent part could guide the paper box to a parallel handrail that allows a perfect blank alignment, correct the deviation, facilitate the subsequent accurate folding of the paper cassette, perfect folding quality throughout the machine. It's based on SCM technology, developed all of drive units with intelligent control and One-key Start Producing. It is applicable for boxes, delivery bags, corrugated boxes, and smoke / wine boxes, gift boxes, art-ware adhesives, etc.

U Series Double Sides Tape Application Machine

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

The whole machine is designed for light machine,the main transmission part adopts synchronous conveyor belt,and the high-precision positioning part adopts precision synchronous gear transmission.

Product introduction:

This model is designed for Corrugated Boxes, especially for Delivery Carton Glue Pasting. It adopts advanced friction feeding method to feed paper with 6 high-quality thickened belts & high-efficiency paper-cutting knife to ensure the accurate / smooth transportation in production. By the composition of the roller with the correction mechanism, the operation is simple and convenient with more accuracy. It's equipped with innovative double-sided adhesive technology, it adapts most of the models of double-sided adhesives. It's set with international common man-machine dialogue mode with a variety of settings at the interface at a glance, the production process can be adjusted according to the actual situation at any time to make changes. It is more flexible to receive paper with high-precision counting electric eye to implement counting mode. It is applicable for boxes, delivery bags, corrugated boxes, and smoke/wine boxes, gift boxes, art-ware adhesives, etc..

PJC-600 Glue Detection System

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Gluing gun Detection System,used for preventing of adhesive-missing, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process.

Product introduction:

This system works for gluing inspection and detection automatically, including adhesive-free, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process. It is easy to set and it operates with high precision monitoring which can be displayed the faulty amount throughout the touch screen. It provides reliable glue detection for Gluing products at speed under 300m/min.The sensor automatically detect where glue is missing or applied incorrectly. It’s widely used in Paper, Carton, Foil, Wood, Metal, Glass and other material products. The faster machine runs, the more important quality control becomes. Therefore, this Detection System becomes more and more necessary for your Gluing Work.

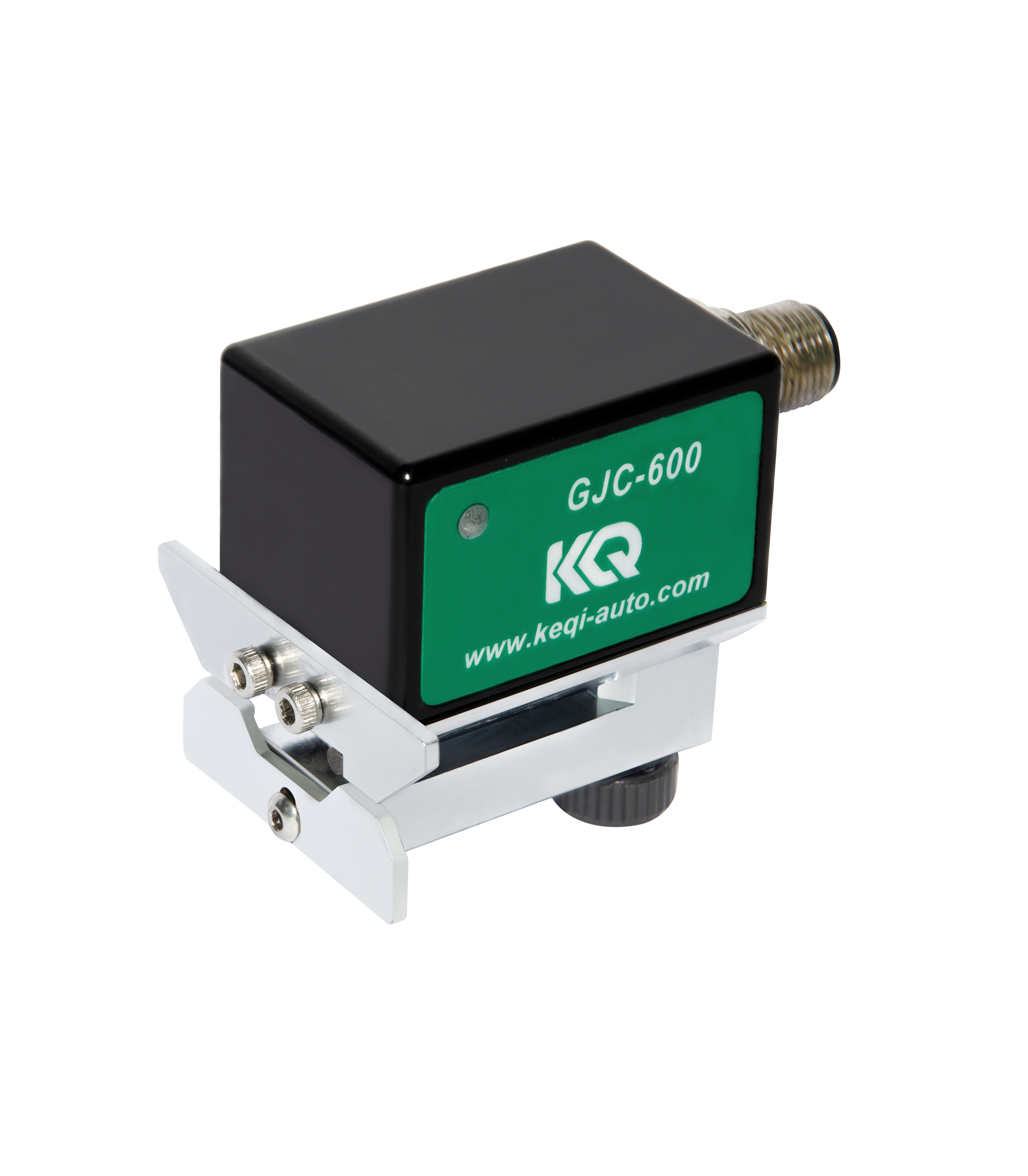

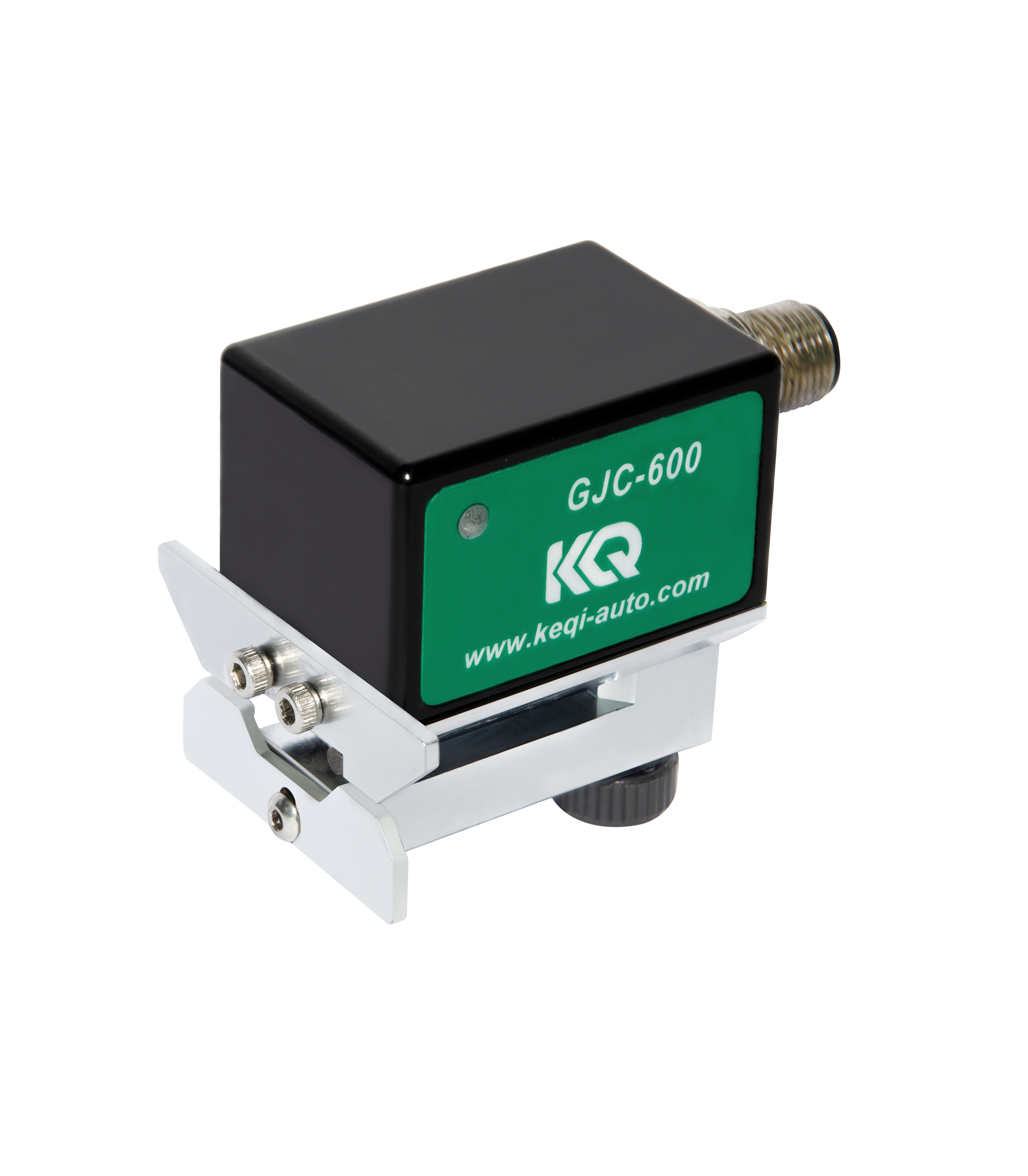

GJC-600 Side Seam Glue Detection System

Innovative highlights of the exhibit:

Innovative highlights of the exhibit:

Gluing gun Detection System,used for preventing of adhesive-missing, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process.

Product introduction:

This system works for gluing inspection and detection automatically, including adhesive-free, adhesive faulty, less adhesives so that ensure the gluing quality and reduce the labour inspection process. It is easy to set and it operates with high precision monitoring which can be displayed the faulty amount throughout the touch screen. It provides reliable glue detection for Gluing products at speed under 300m/min.The sensor automatically detect where glue is missing or applied incorrectly. It’s widely used in Paper, Carton, Foil, Wood, Metal, Glass and other material products. The faster machine runs, the more important quality control becomes. Therefore, this Detection System becomes more and more necessary for your Gluing Work.