Lohmann's "Smart Bonding for Flexo" at the Drupa

Time:2016-03-23 From:

[Source: News from Lohmann's website] In Hall 15, booth B22, the "Bonding Engineers" will show innovative adhesive solutions specifically for the flexographic printing industry. Quite in line with Lohmann's general concept, the "Smart Bonding Approach", "Smart Bonding for Flexo" means that we closely accompany the customer with advice and support, beginning from the initial idea up to the integration of the applicable adhesive solution in his application process. The "Bonding Engineers" at Lohmann thus provide the ideal technical approach, the right tools, the right product and an individually tailored service.

It is not only for this reason that Lohmann has been renowned for decades as a reliable partner for the printing industry. The successful product range DuploFLEX plays a particularly important role, because it sets new standards in the mounting of flexographic printing plates.

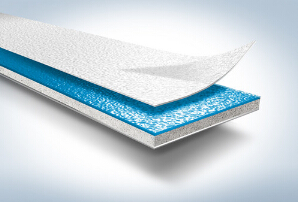

Today, the possibilities in flexographic printing are greater than ever. Equally high are the expectations on the part of customers for perfect printing results, and therefore the choice of the right plate mounting tape is a key factor for the flexographic printer. Acting as a substructure and a damping factor, the foam tape must also facilitate an optimal printed image. The product range DuploFLEX 5 consists of several compressible tapes that differ in their foam hardness and adhesive performance. The product line DuploFLEX HP 5 is available for difficult and demanding print jobs. The HP (high performance) foam used in this case plays a decisive role: It possesses a very high degree of stability and recovery characteristics that meet the required demands. It thus counteracts machine vibrations, prevents vibration marks in the printed image and is especially suitable for long and fast print jobs.

Lohmann’s "Bonding Engineers" are also ideally positioned in the field of direct corrugated board printing. As a compressible base, the product range DuploFLEX CB (Corrugated Board) ensures the best printing results in high-quality post-print. In direct corrugated board printing, the line of products convinces with its strengths such as: enhanced print quality and improved cost-effectiveness.

New to the market segment Graphics is the product range DuploFLEX EB (Engineered Bonding). In this case, the proven features of the DuploFLEX 5 range are combined with new, product-specific properties. The basis is our in-house development of a new adhesive designed specifically for these products. Thus, Lohmann again goes one step ahead in the development of suitable products for flexographic printing and gets quite close to squaring the circle. In addition, it is resistant to solvents and possesses a greater scope in respect to heat and humidity. When it comes to an especially challenging print job (e.g. small cylinder size or hard printing plates), DuploFLEX EBX comes into play. The DuploFLEX EB range is suitable for a wide variety of foams, from very soft to very hard, with a maximum width of 1.380mm.

The partnership between the companies TRESU and Lohmann will be another topic at the Drupa 2016. Since July 2013, the Danish provider of flexographic printing presses and the German provider of customized adhesive solutions have been working closely together. The aim of this partnership is to optimize the performance of plate mounting tapes for different requirements in high-speed flexographic printing. The first results of this partnership will be shown at the Drupa. In Hall 10, booth D54, TRESU will show, among other things, printing results with Lohmann adhesive tapes.

All in all, at the Drupa 2016, the experts of Lohmann will present a wide range of products for the graphic industry and will gladly provide information and be available for more intensive discussions.