Highlights:

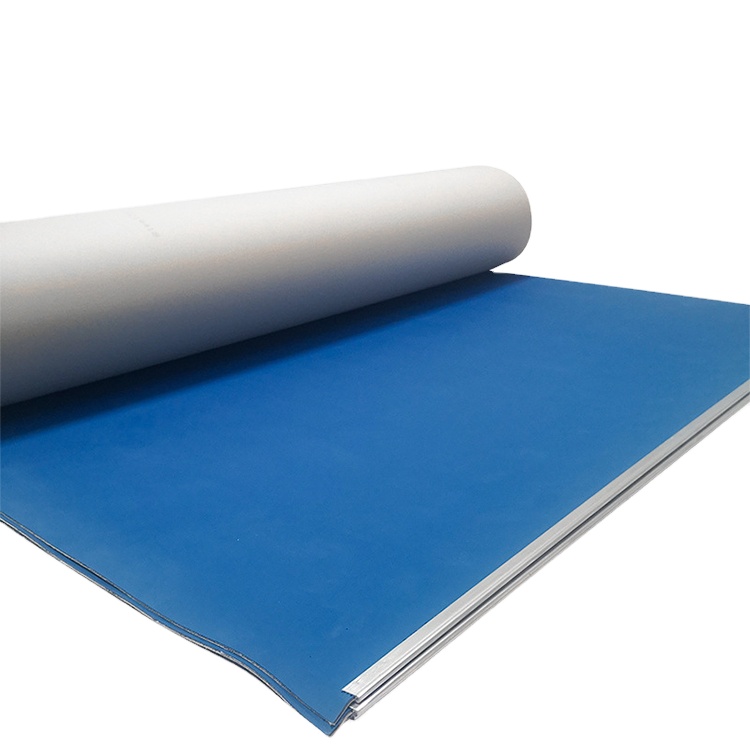

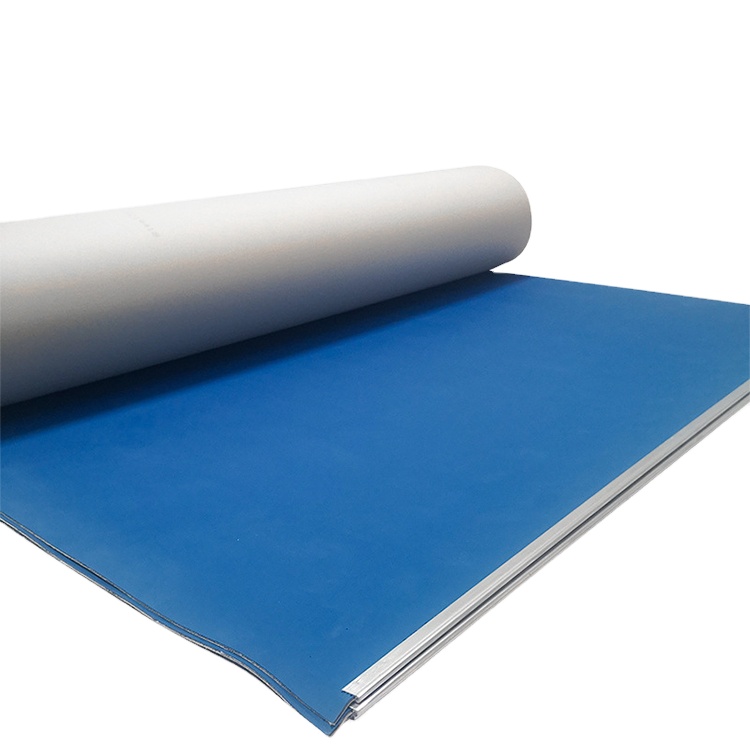

Special for high-speed printing, high-density fabric layer. Stable thickness, more durable, effective resistance to impact, faster recovery

Detail information of products:

High Speed Dedicated

Thickness specification: 1.68mm

Offset printing blanket is different from general rubber products, rubber cloth it is laden with the ink on the plate is passed on to the paper, in order to make the printing ink evenly, points clear, rich layers, offset printing rubber cloth must have moderate hardness, compressive deformation is small, good ink performance and low elongation, etc, in chemical properties on it should have already adsorption ink and adsorption effect of the education version fluid and to have not react with oil, and potions and by oil, liquid erosion performance. And because it is lithography, so the blanket flatness requirements are very high.

Maintenance:

Blanket replacement is due to abnormal factors caused by the reasons. (That is: small area can not change a large area, not resistant to cleaning and very paper folding Angle, double sheet, pulp block)

It is suggested that you can do the following:

Continuous printing of 12 pieces of paper, that can automatically restore, or stop machine to replace the lining or gun bottom paper, and then print 22 pieces of paper to restore, and other brands generally in 0.20 m0. About 30mm, if the problem still appears, please adjust the use according to your experience.

Clean:

We recommend that users use the following steps to clean the blanket:

1. Use warm water to wipe away water-soluble substances such as paper powder.

2. Use no damage to the blanket car wash water or solvent wipe ink and other solvents dissolved in the material.

3. Such as rubber city surface calcium magnesium ion deposition can choose to contain citric acid car wash water or weak acid such as vinegar for cleaning.